If you do neither, don’t increase the viscosity or the speed, the separation of the two plates will diminish to increase the shear rate resulting in potential plate-to-plate contact. Or we can increase the shear rate to offset the added normal stress or load, by increasing the speed to maintain a hydrodynamic film. The right viscosity is matched against the increased shear force per area.

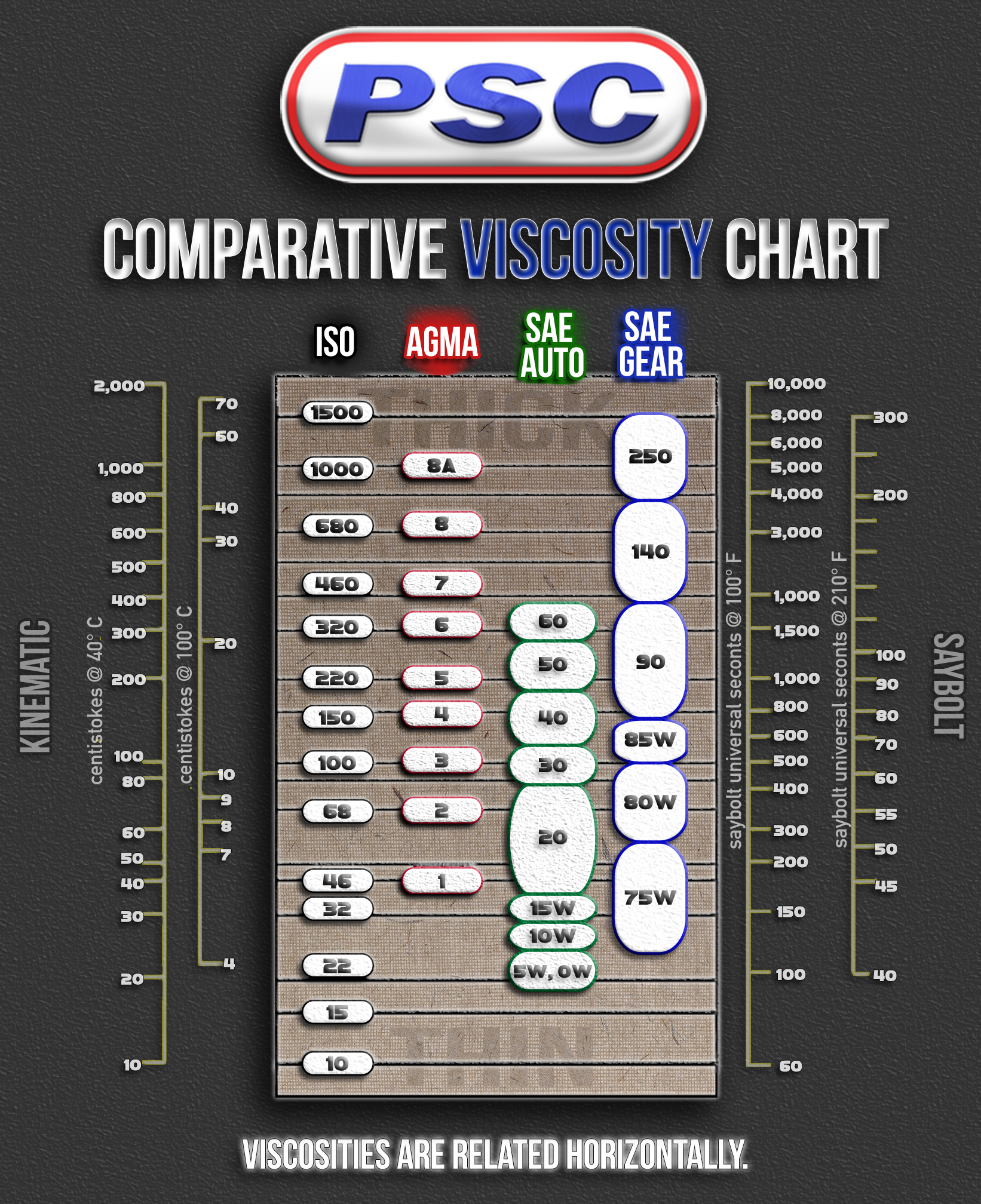

#VISCOSITY COMPARISON CHART FULL#

Therefore, going back to our viscosity equation, if we increase the shear force via added weight on the top sliding plate, we need to see an increase in the shear rate or an increase in viscosity A higher viscosity fluid will maintain the full fluid film longer keeping the plates in a hydrodynamic lubrication regime. Shear stress, on the other hand, acts parallel to the plate pushing it to the right. Normal stress is the vertical downward force on the plate, or the force perpendicular to the plate. Normal stress is the load on, or weight of, the top sliding plate. Part of the shear force per area mentioned previously that we haven’t talked about yet in our viscosity equation is the nominal stress besides the shear stress exerted on the plate. Then, going back to our equation, we need to lower the viscosity of the liquid to offset the increase in shear rate so that the same force is required to move the plate at the same speed. Here I imagine fewer cards in my deck of cards. This is because each of the fewer layers of liquid must shear farther to keep the oil next to the sliding plate moving with it and the liquid layer next to the stationary plate still. If we keep the top plate moving at the same speed and decrease the film thickness while still keeping the plates from touching each other, the rate of liquid shearing also will increase. If we don’t decrease the viscosity, more shear force is needed to increase the speed, and that force is exerted against the liquid’s viscosity, or resistance to flow, and that increased energy results in heating the liquid, possibly overheating.

Therefore, to keep the shear force (F) constant while increasing the shear rate (R) via the faster sliding speed, we need to decrease the viscosity (V). If we increase the speed up the sliding plate, it makes sense that the rate of shear (R) in the liquid will increase. The rate of shear is dependent on the speed and distance between the plates. I imagine the layers of liquid in this scenario to be similar to a deck of cards. Shearing happens to the liquid layers in between the two plates. The liquid next to the sliding plate moves close to the speed of the plate while the liquid next to the stationary plate remains still. The bottom plate is stationary, and the top plate is sliding left to right. So, looking at Figure 1, we have two plates lying parallel to each other, completely separated by a liquid full fluid film with no plate-to-plate contact-in other words, a hydrodynamic lubrication regime. However, I want to relate it in terms I experienced in my growing up on the farm in Missouri, because that is my “fallback” to understanding most things. What does that mean? I understand the equations used to measure and quantify viscosity due to my studies in the engineering discipline. Simply stated, viscosity (V) is equal to the shear force per area (F) divided by the shear rate (R). Remember hitting a water puddle at speed resulting in your car hydroplaning? Hopefully you slowed down and the car regained contact with the road. The more viscous syrup may be considered “thick.” Yet, under the right conditions, water can lift your car off of the road. We may call water “thin” relative to maple syrup, which doesn’t flow so freely. We can tell water flows quickly, demonstrating its low viscosity. We do have routine experiences that demonstrate viscosity variations. It is the lubricant’s resistance to flow. It is the most important characteristic of a lubricant.

To discuss lubrication fundamentals, we must talk about viscosity.

0 kommentar(er)

0 kommentar(er)