Harris in 1913! Since then, many extensions have been made to this formula, but the basis still stands.

A formula that is very useful and that I often use myself, is the EOQ formula, developed over a hundred years ago by Ford W. The question is whether they also take into account how much we actually need for our customer and what are the costs of keeping inventory?Īs a manager, it is our duty to take all relevant costs into account when determining lot sizes. In doing so, they will mainly take into account the costs of preparing an order or the changeover costs.

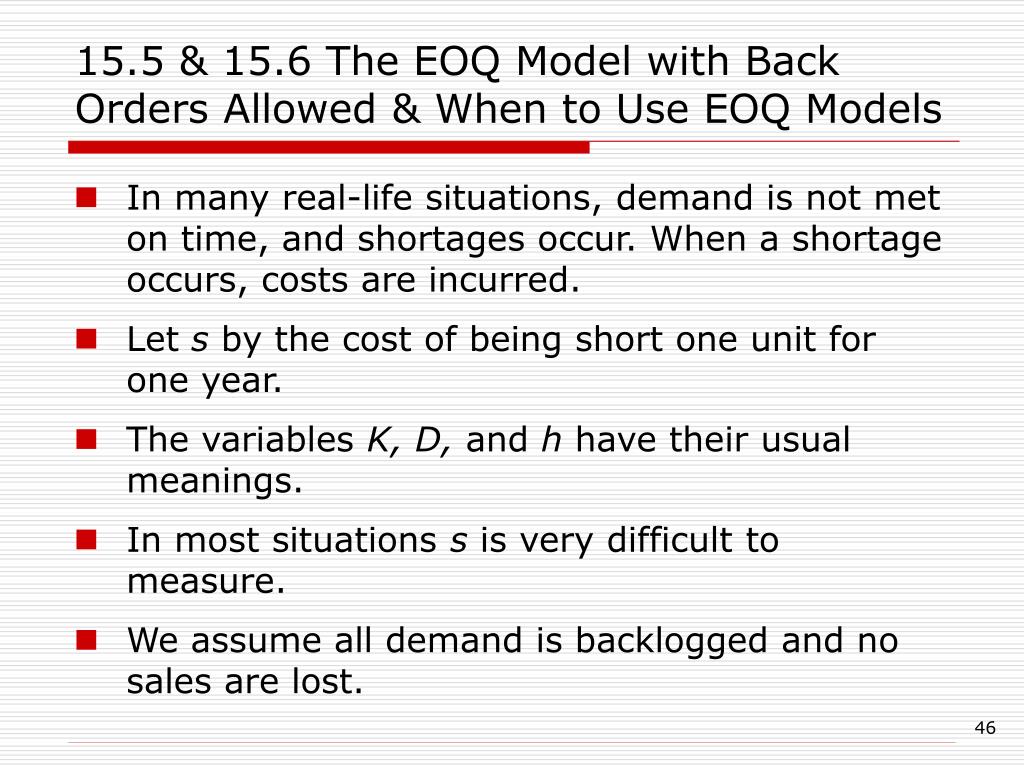

#Eoq with back orders find average time to meet demand full

How do you go about determining this lot size? Often your supplier or your production manager will propose some value, for example a full pallet or a minimum number of hours of production. But when creating a new article, you will be asked to enter an order size in your ERP system. In most ERP systems, a lot size can be defined, to ensure that, when you place a purchase order or a production order, you get a proposal of how many pieces, litres or kg you have to order or produce. The question is whether they also take into account how much we actually need for our customer and what are the costs of keeping inventory? In that case, you can no longer decide on experience and feeling how much you will buy of each item. Moreover, it usually concerns hundreds, and often thousands or even tens of thousands of references. Often the user is the customer, or the production department. The purchaser therefore already has less “feeling” about a product. In a company, the purchaser is often not the person who actually uses the product. It probably only concerns a few dozen of items and you consume them yourself, which makes it easily manageable, although we often also have to throw away food of which we bought too much. But how do you determine the order size for purchasing or production?įor your freezer, you do so on “gut” feeling.

Maybe you can buy smaller quantities of some products so that you have more space for others. You decide which products to store and how much. A few weeks ago, in another LinkedIn article, I compared stock management in your warehouse to your freezer at home.

0 kommentar(er)

0 kommentar(er)